ESD Equipment

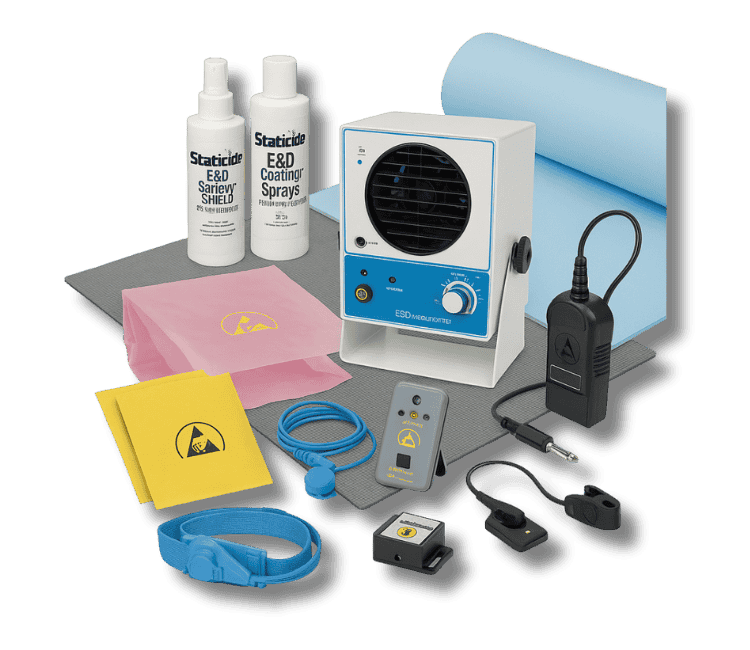

Automatrix ESD Equipment is designed to prevent electrostatic discharge damage in sensitive electronic environments. Our range includes ESD workbenches, wrist straps, floor mats, storage bins, and chairs—engineered for maximum static protection. Each product uses conductive or dissipative materials to safely neutralize static charges, ensuring safe handling of components. Suitable for electronics manufacturing, laboratories, cleanrooms, and repair facilities, our ESD solutions comply with international static control standards. With ergonomic designs, durable materials, and reliable performance, Automatrix ensures safety, product quality, and operational efficiency in electrostatic-sensitive workplaces across multiple industries.

Category: Safety, ESD & Cleanroom Systems

Static Dissipation: Uses conductive or dissipative materials to safely neutralize harmful electrostatic charges.

Durable Materials: Built from high-quality, wear-resistant materials for long-lasting performance under constant use.

Ergonomic Design: Designed for operator comfort and efficiency during extended work periods handling sensitive devices.

Compliance Standards: Meets IEC, ANSI/ESD, and other relevant electrostatic discharge control regulations globally.

Easy Maintenance: Surfaces and components are simple to clean, ensuring consistent ESD protection performance.

Customizable Options: Available in different sizes, colors, and configurations to meet workplace requirements.

Full Coverage: Provides head-to-toe static protection including furniture, tools, and operator accessories.

Integration Ready: Compatible with other cleanroom or static control systems for comprehensive protection.

- Electronics Manufacturing: Protects printed circuit boards and microchips from static-induced failures during assembly.

- Repair Centers: Prevents damage to sensitive electronics during troubleshooting, soldering, and repairs.

- Cleanrooms: Maintains controlled static-free environments for precision manufacturing processes.

- Testing Laboratories: Ensures accurate measurement results by eliminating static interference with instruments.

- Aerospace Industry: Protects delicate avionics and electronic components from electrostatic damage during assembly.

- Telecommunications: Prevents static damage in production and maintenance of communication equipment.

- Automotive Electronics: Safeguards advanced control units and sensors from electrostatic discharge during handling.

- Medical Device Manufacturing: Ensures safety of sensitive diagnostic and treatment devices during production.

- Voltage Range: Effective for static control in environments up to 100 volts sensitivity.

- Material Types: Includes rubber, vinyl, polyester, and conductive plastic materials.

- System Integration: Works with ionizers, grounding systems, and other static protection devices.

- Mobility Options: Portable ESD stations and mobile carts available for flexible workspace arrangements.

- Color Codes: Offered in industry-standard ESD-safe colors for quick identification.

- Power Requirements: Some devices include powered ionizers requiring standard AC supply.

- Temperature Tolerance: Suitable for use in varied manufacturing climate conditions.

- Custom Sizes: Tailored dimensions available for specific workstation or facility layouts.