Heaters and Heating Elements

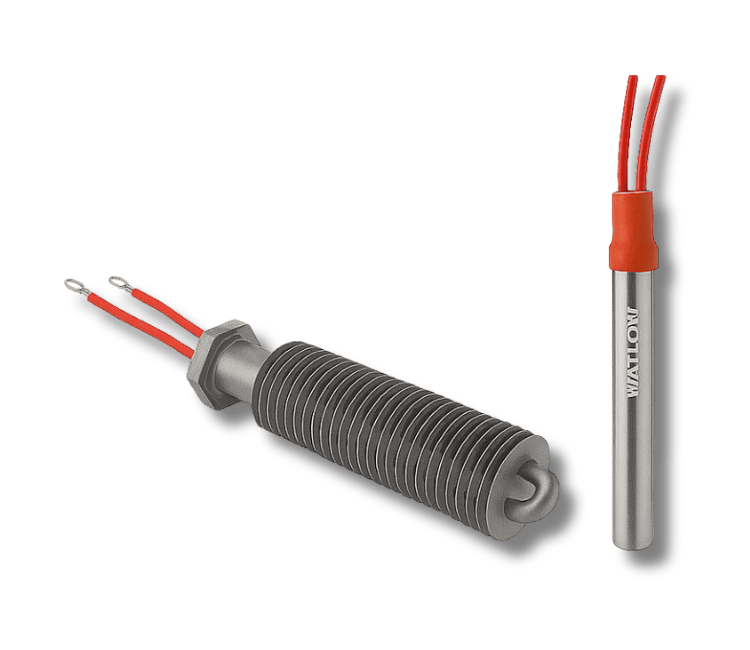

Automatrix Heaters and Heating Elements provide reliable, efficient heat for diverse industrial processes and environments. Our range includes immersion heaters, infrared panels, tubular elements, and flexible silicone heaters, each designed for precise temperature control and durability. Built to withstand demanding conditions, these heating solutions improve process efficiency while reducing energy costs. Whether for liquid heating, air warming, or surface applications, Automatrix heaters ensure uniform heat distribution, minimal maintenance, and safe operation. Ideal for manufacturing, laboratories, food processing, and HVAC systems, they meet stringent performance and safety standards across global industries.

Category: Lighting, Heating & Ventilation

- Energy Efficiency: Optimized designs deliver maximum heat transfer while minimizing power consumption for operational costs.

- Durable Construction: Made from high-quality materials to withstand harsh industrial environments and extended operating cycles.

- Uniform Heating: Ensures consistent temperature distribution for improved product quality and process reliability.

- Fast Response: Quickly reaches target temperatures, reducing downtime and improving operational efficiency.

- Corrosion Resistance: Suitable for heating water, chemicals, and corrosive solutions without performance degradation.

- Custom Designs: Available in varied shapes, wattages, and mounting styles for specific application needs.

- Safety Features: Integrated controls prevent overheating and ensure safe, reliable operation in critical environments.

- Low Maintenance: Designed for long service life, reducing repair frequency and associated costs significantly.

Process Heating: Maintains consistent temperatures for industrial manufacturing and material processing.

Liquid Heating: Immersion elements efficiently heat water, oils, and chemical solutions.

Air Heating: Finned heaters provide uniform airflow heating for HVAC and drying systems.

Surface Heating: Flexible silicone heaters warm equipment surfaces and maintain operational efficiency.

Food Processing: Supports safe, controlled heating for cooking, drying, and preservation applications.

Laboratories: Ensures precise temperature control for experiments and sample preparation.

Plastic Molding: Maintains mold temperatures for improved product finish and dimensional accuracy.

Freeze Protection: Prevents fluid and equipment freezing in low-temperature environments.

Voltage Range: Operates with various industrial power supplies, including single-phase and three-phase connections.

Mounting Options: Supports flange, screw-in, clamp-on, and adhesive installation methods.

Control Systems: Compatible with thermostats, timers, and advanced process controllers.

Fluid Types: Suitable for water, oils, and a variety of industrial chemicals.

Temperature Range: Operates across wide temperature limits to suit diverse heating applications.

Size Variations: Available in multiple lengths, diameters, and flexible configurations.

Material Options: Manufactured from stainless steel, copper, or specialized alloys for enhanced performance.

Safety Compliance: Meets relevant industrial heating equipment safety and quality certifications.

Top Brands