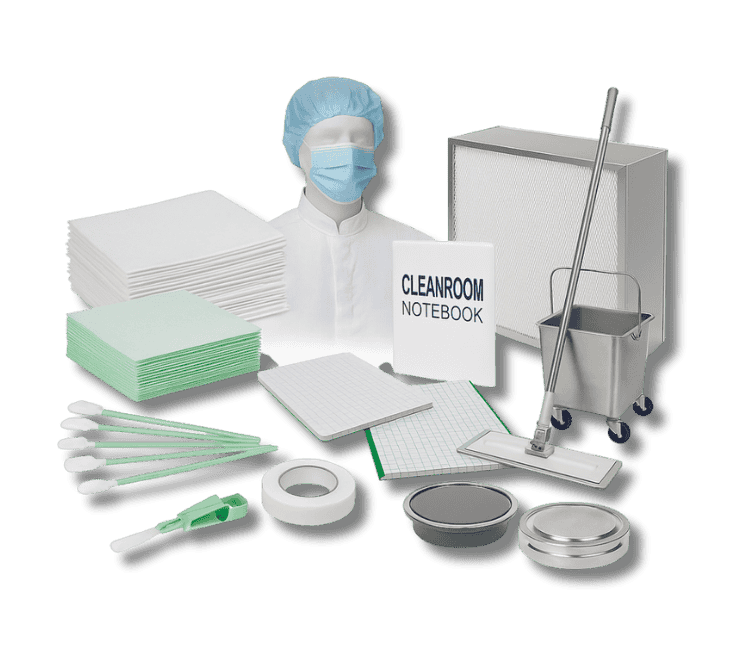

Cleanroom Equipment

Automatrix Cleanroom Equipment ensures controlled environments essential for pharmaceutical, electronics, medical, and research industries. Our range includes laminar flow cabinets, cleanroom workbenches, air showers, pass-through chambers, and storage solutions—engineered to maintain strict contamination control. Each product is built from durable, easy-to-clean materials and designed to meet ISO cleanroom classifications. Featuring HEPA filtration, ergonomic designs, and efficient airflow systems, our equipment supports precision work while protecting both personnel and products. Suitable for critical manufacturing and testing environments, Automatrix delivers reliability, safety, and compliance with stringent cleanroom standards across various industrial and laboratory applications.

Category: Safety, ESD & Cleanroom Systems

- HEPA Filtration: Provides high-efficiency particle removal ensuring cleanroom air meets ISO classification requirements consistently.

- Durable Construction: Built from corrosion-resistant, smooth-surface materials that are easy to clean and disinfect.

- Ergonomic Design: Designed for operator comfort, reducing fatigue during long working periods in controlled environments.

- Low Noise Operation: Engineered for quiet performance to improve focus and comfort in cleanroom tasks.

- Energy Efficient: Uses optimized airflow systems reducing power consumption while maintaining contamination control standards.

- Customizable Options: Available in various sizes, configurations, and features to meet specific application needs.

- Compliance Ready: Meets GMP, ISO, and other relevant cleanroom certification standards globally.

- Easy Maintenance: Designed for straightforward filter replacement and routine cleaning with minimal downtime required.

Pharmaceutical Production: Ensures contamination-free manufacturing of drugs and medical devices consistently.

Electronics Manufacturing: Protects sensitive components from dust, static, and airborne contaminants during assembly.

Biotechnology Labs: Maintains sterile conditions for research, testing, and development processes effectively.

Food Processing: Supports hygienic handling and packaging of sensitive food products meeting safety regulations.

Medical Facilities: Provides contamination control in surgical preparation and sterile storage areas.

Research Institutions: Ensures controlled conditions for experiments requiring particulate-free environments.

Aerospace Industry: Protects precision parts manufacturing from contamination affecting performance.

Optical Industry: Maintains dust-free conditions for lens and optical instrument production quality assurance.

Cleanroom Classes: Suitable for ISO Class 3 to Class 8 controlled environments worldwide.

Material Options: Available in stainless steel, powder-coated steel, and high-grade polymers.

Filter Types: Compatible with HEPA and ULPA filtration systems for various contamination control levels.

Power Supply: Supports standard industrial voltages for global compatibility in cleanroom facilities.

Installation Type: Available in floor-standing, wall-mounted, or modular configurations.

Mobility Options: Can be equipped with casters for easy relocation within controlled areas.

Integration Ready: Designed for seamless integration with other cleanroom systems and equipment.

Custom Sizes: Built-to-order dimensions to suit specific facility layouts and operational requirements.