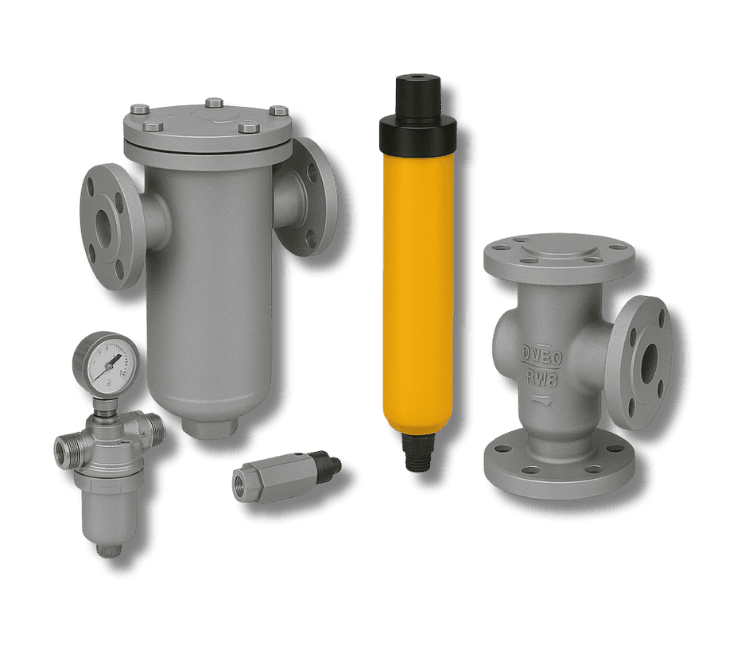

Industrial Filters & Strainers

Automatrix industrial filters and strainers are designed to remove solids, debris, and contaminants from liquid, gas, and steam systems, ensuring optimal equipment performance and protecting downstream components. Available in Y-strainers, basket strainers, self-cleaning filters, cartridge filters, and bag filters, our solutions deliver high efficiency, low pressure drop, and long service life. Built from corrosion-resistant materials, they withstand demanding industrial environments and varying operating pressures. Suitable for water treatment, chemical processing, oil and gas, power generation, and food industries, Automatrix filters and strainers maintain system cleanliness, reduce maintenance costs, and improve overall process reliability.

Category: Pneumatics, Hydraulics, Fluid & Air Handling Equipment

Variety Offered: Includes Y-strainers, basket, cartridge, bag, and self-cleaning types for diverse filtration needs.

Durable Construction: Built from stainless steel, carbon steel, or high-grade polymers for long-lasting service life.

High Efficiency: Effectively removes particulates and contaminants to maintain clean system operation and protect equipment.

Low Pressure Drop: Engineered designs minimize pressure loss while maintaining maximum flow rates through the system.

Easy Maintenance: Accessible designs allow quick element replacement or cleaning without extensive downtime or disassembly.

Corrosion Resistance: Materials selected to withstand chemicals, moisture, &environmental exposure over extended periods.

Customizable Options: Multiple mesh sizes, filter media, and housing configurations to meet specific application requirements.

Reliable Performance: Designed and tested for consistent filtration efficiency under varying flow and pressure conditions.

- Water Treatment: Removes sediment, debris, and impurities from water in treatment and distribution systems.

- Chemical Processing: Filters aggressive chemicals to protect pumps, valves, and downstream processing equipment.

- Oil & Gas: Ensures clean fuel, lubricants, and process fluids in refining and drilling operations.

- Power Generation: Protects boilers, turbines, and heat exchangers from harmful particulates and contaminants.

- Food & Beverage: Maintains hygiene by filtering process water, syrups, or other liquids in production lines.

- Pharmaceuticals: Provides sterile filtration for water, solvents, and liquid ingredients in sensitive manufacturing environments.

- HVAC Systems: Removes debris from chilled or heating water loops to prevent fouling and system blockages.

- Irrigation Systems: Filters water to prevent clogging of sprinkler heads, drip emitters, and irrigation pipelines.

- Material Selection: Compatible with stainless steel, carbon steel, brass, PVC, and polypropylene piping systems.

- Seal Compatibility: Works with EPDM, NBR, PTFE, and Viton seals for various chemical and temperature conditions.

- Connection Types: Supports threaded, flanged, welded, and clamp connections for installation flexibility.

- Flow Capacities: Handles low, medium, and high-flow applications without sacrificing filtration performance.

- Media Types: Filters water, oil, steam, air, and chemical solutions effectively across industries.

- System Integration: Fits into manual or automated process systems for seamless filtration control.

- Maintenance Access: Designed for easy element removal and cleaning without requiring complete system shutdown.

- Standards Compliance: Meets ISO, ANSI, and CE quality standards for safety and operational reliability.

Top Brands